Body

In stretch film production, slight color differences between rolls or batches are a common concern for buyers, especially in logistics, warehousing, and manufacturing industries.

These variations are usually not random. In most cases, they come from three core factors:

1. Raw Material Batch Differences

Stretch film is primarily made from polyethylene resin.

Even when sourced from the same supplier, different production batches may vary slightly in molecular structure, melt index, or base transparency.

These micro-variations can affect how light passes through the film, resulting in subtle color changes—especially noticeable in clear, thin, or high-stretch films.

2. Influence of Additives

Additives such as:

anti-block agents

slip agents

UV stabilizers

recycled material modifiers

can directly impact film appearance.

Differences in additive type, dosage, or dispersion uniformity may lead to visible color shifts, particularly in recycled or specialty stretch films.

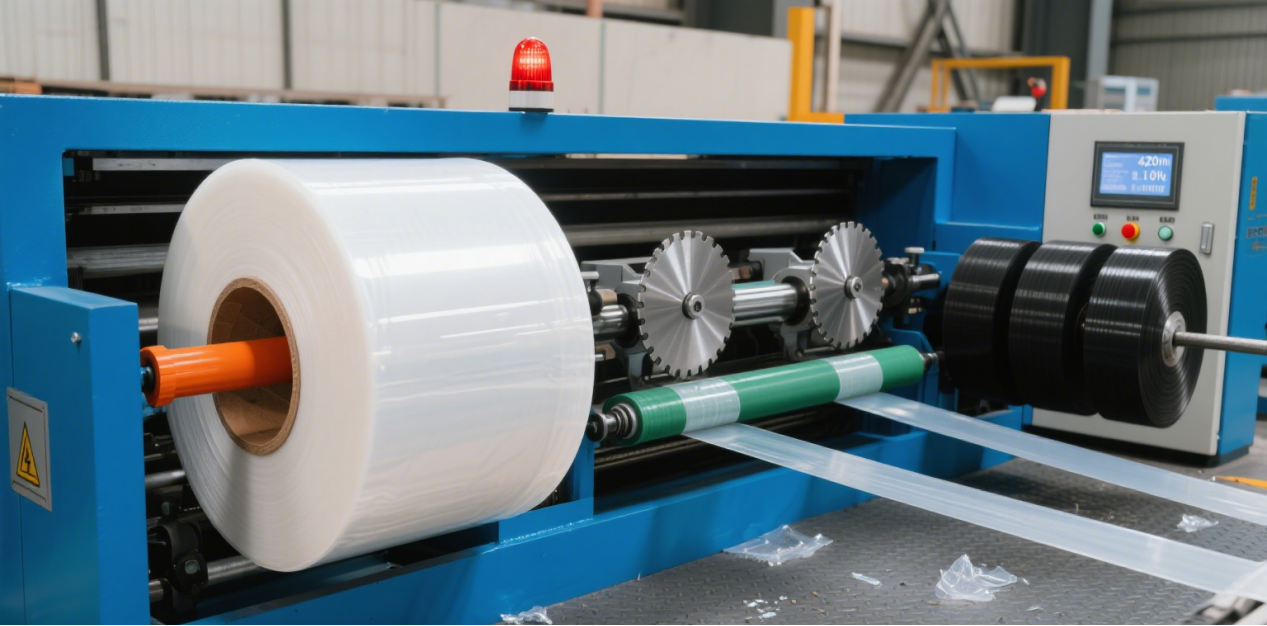

3. Processing & Manufacturing Conditions

Processing parameters also play a critical role, including:

extrusion temperature

screw speed

cooling rate

stretching ratio

If these conditions are not perfectly stable, the film’s surface structure and optical properties may change, causing color inconsistency.

Final Thoughts

Color variation does not necessarily mean poor quality.

What truly matters is performance consistency—stretchability, tensile strength, puncture resistance, and load stability.

At professional manufacturing facilities, strict raw material control, standardized formulations, and stable processing are essential to minimize color deviation and ensure reliable quality batch after batch.

Post time: Dec-25-2025