Description:

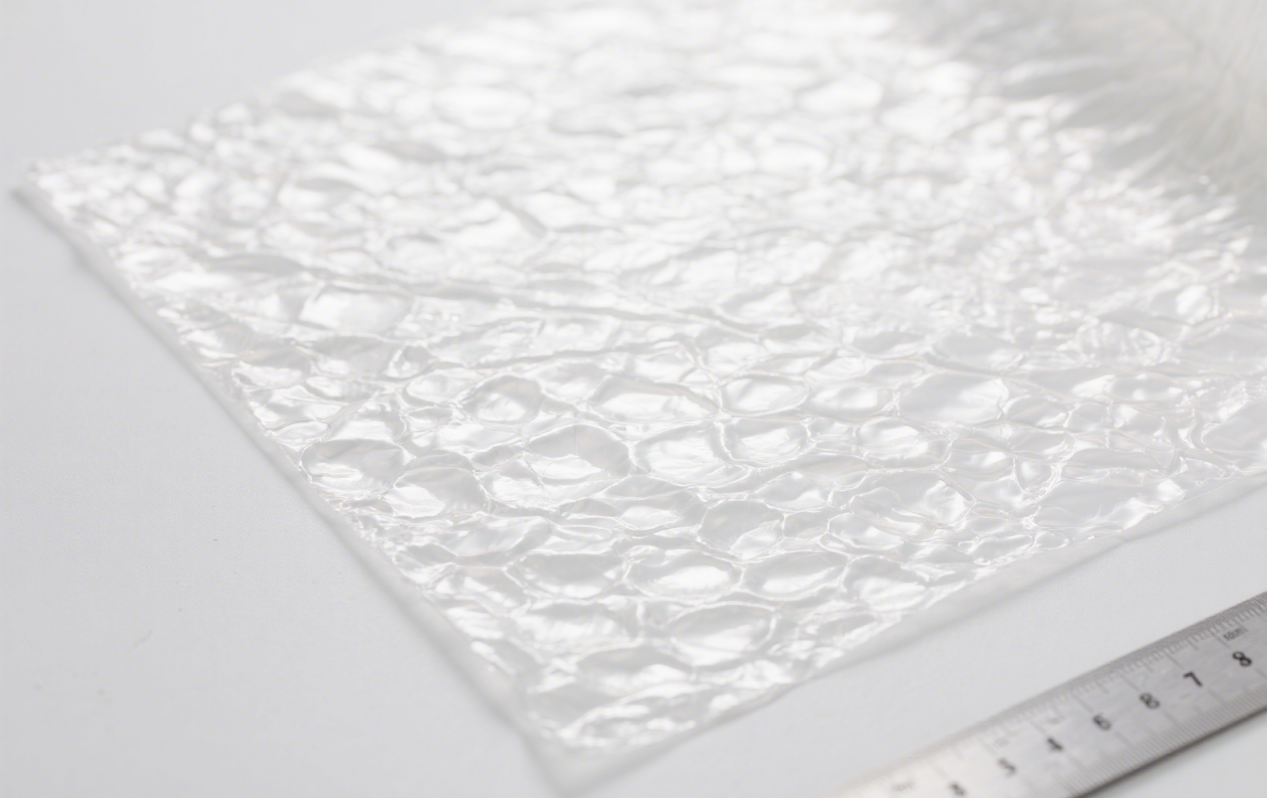

Roll bulging (“bagging” or “bubble” in wound film rolls) is a common but costly defect that originates from uneven internal stress distribution in the roll. It typically appears only after winding, unwinding, or delivery — making it a “silent” production killer. This paper analyzes the root causes from both materials science (micro-scale viscoelastic behavior and interlayer interaction) and process/equipment physics (tension control, thickness variation, contact pressure, surface properties, thermal effects), and gives targeted recommendations for systematic diagnosis and prevention.

Keywords: film winding, roll bulge, winding tension, viscoelasticity, thickness nonuniformity

01 Introduction

Among the many quality problems in film production, roll bulging during winding is one of the most troubling. It often hides inside the roll and only becomes obvious after transport or during customer use, causing substantial rework, rejects, and customer complaints. To eliminate it we must investigate like detectives — peeling back layers to find fundamental causes. This article performs a focused analysis from two complementary perspectives: material-level mechanisms and macro-scale process/equipment factors.

02 The Nature of Roll Bulging

At its core, every bulge is an external symptom of uneven internal stress distribution inside the roll. A simple analogy: a perfectly stacked pile of paper looks flat; insert a few creased or misaligned sheets and the stack becomes wavy. Film winding behaves the same way but with greater complexity — the combination of stored mechanical stress, interlayer interaction, and process variability produces localized outward displacement that we see as a bulge.

03 Microscopic Perspective — Why the film “remembers” and pushes back

(1) Viscoelastic memory and asynchronous relaxation

Film is not a purely elastic material; it is viscoelastic. During winding the film is stretched and tightly held on the core, storing considerable internal stress (like a compressed spring). Over time the film relaxes. If relaxation occurs unevenly across the roll (different radial positions, local temperature differences, or material heterogeneity), internal stress imbalance appears. When constraints between layers are insufficient to rebalance these stresses, high-stress zones expand outward and form bulges.

Ideal winding assumes perfect adhesion or no slip between layers. In practice, new layers exert shear forces on underlying layers. If local friction is too low (very smooth areas) or compressive pressure is excessive, micro-slips occur. Repeated, non-uniform micro-slips accumulate into macroscopic misalignments and permanent bulges.

04 Macroscopic Perspectives — process and equipment causes

Microscopic mechanisms make bulges possible; macroscopic conditions decide where and how severely they manifest. Key contributors include:

(1) Tension control Tension is the heart of winding. Overly high winding tension stores excessive initial stress, creating a latent instability. More dangerous are tension fluctuations — speed changes, guide-roll bounce, or web breaks cause sudden stress spikes that concentrate in the layer being wound at that moment, producing a localized “danger layer.”

(2) Thickness nonuniformity

Even micrometer-scale thickness deviations act like a wedge: each successive wrap amplifies the local height. A persistent thickness stripe becomes a longitudinal, width-aligned hard bulge after many layers accumulate.

(3) Contact pressure and core hardness

- Contact pressure: The nip/press roller must be set to compress layers sufficiently to remove air and ensure conformity. Too little pressure yields soft bulges (air gaps); too much pressure increases interlayer shear and may create hard bulges, especially near the core or roll edges.

- Core hardness & straightness: A soft, out-of-round, or bent core imposes an already distorted geometry on every layer. Under winding tension, this seed distortion magnifies into a pronounced bulge that later processes cannot correct.

(4) Non-uniform surface properties (friction distribution)

Variation of friction coefficient across the film width — from uneven corona treatment, non-uniform slip agent coating/migration, or contamination — causes some zones to “grab” tighter and others to slide. Under winding shear, low-friction bands preferentially slip and generate bulges in the corresponding locations.

Film properties and relaxation behavior are temperature-sensitive. If a roll traps heat (poor cooling after extrusion, localized friction heating, or thermal gradients during winding), inner layers relax differently from outer cold layers. This thermal mismatch accelerates stress redistribution and promotes bulging.

05 Summary

Roll bulging is not a single-cause defect; it is a systemic imbalance. Material viscoelasticity, interlayer shear, tension dynamics, thickness irregularities, surface treatment non-uniformity, core quality, and thermal conditions interact to determine whether, where, and how severely a bulge appears. Effective remediation therefore requires a multi-dimensional, system-level approach rather than a one-off fix.

06 Conclusion & Practical Recommendations

To tame roll bulging, manufacturers must combine material control, process stabilization, equipment specification, and environmental management. Key practical actions:

• Tension management — stabilize line speed and implement closed-loop tension control; avoid large instantaneous speed or tension transients; monitor tension profile and log spikes.

• Thickness control — deploy inline thickness gauges; trace and correct extrusion or die issues that produce stripes; implement real-time alarms for persistent deviations.

• Nip/roller optimization — set nip pressure to remove air without inducing excessive shear; validate roller surface condition and alignment.

• Core specification — use straight, sufficiently rigid cores and check runout; avoid soft or deformed cores under high-tension winding.

• Surface uniformity — ensure uniform corona treatment and controlled slip-agent application; prevent contamination and manage additive migration.

• Thermal control — provide consistent cooling or controlled post-wind relaxation; avoid rapid temperature gradients; consider annealing/relaxation steps for sensitive films.

• Monitoring & QA — inspect roll profile (visual & laser), perform sample unwind tests, and use IR or acoustic sensors where appropriate; keep standardized procedures for storage and transport to avoid post-wind stress changes.

Only by diagnosing and optimizing across materials, equipment, process settings, and storage/thermal conditions can producers reliably prevent bulging and deliver stable, high-quality rolls.

Post time: Nov-25-2025